Making Correct Hydraulic Drive Motor Connections

Each travel drive unit is given a unique identification plate for displaying its individual characteristics. The plate will include all the necessary model, serial and part number information to properly identify the drive. If you can't read your drive's plate, remember that there is an identical drive on the other side that may have a legible plate.

Our Partners will always attempt to get this information from you, but if the plate is missing or damaged, there are other ways to identify your drive. Some drives have distinctive markings or casings. Visit our travel drive manufacturers page to see if you can recognise your drive from the photos shown.

Making incorrect hydraulic drive motor connections can at worst destroy the final drive. This post will help identify the hydraulic connections relevant to different types of machine.

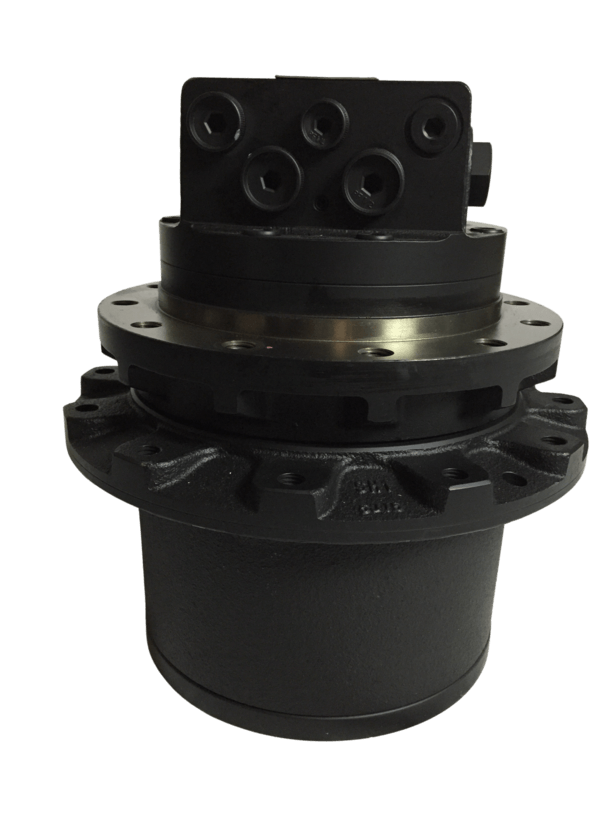

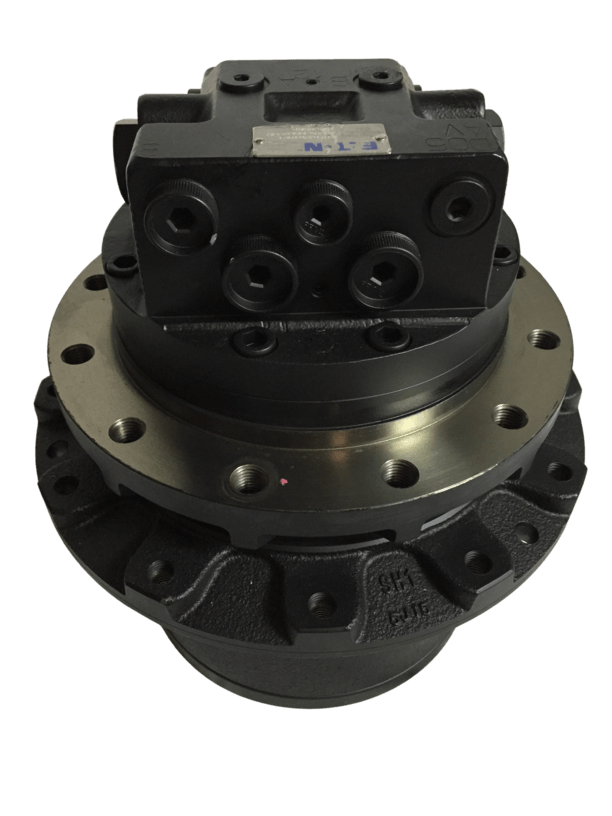

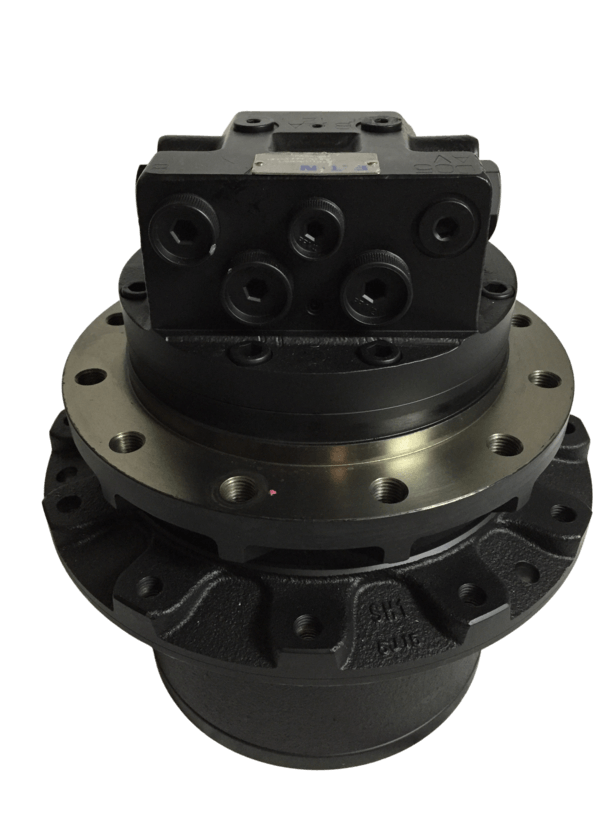

Read this article in association with these images of final drives for mini excavators and large machines, single speed and two speed, integrated and 'plugin' types. These may help in finding a hydraulic track drive that is similar to your machine.

There may be 2, 3, 4 or sometimes 5 hydraulic connections to a hydraulic track drive and gearbox:

- Two hydraulic lines to power the motor. These are the flow and return lines connected to the A & B ports (see images).

- A case drain / leak-off. It is very important to connect this to the correct C port — See below.

- A two speed line to control the travel motor speed via the D port.

- A brake line. If fitted it is usually connected to the gearbox rather than the travel motor.

A & B Ports (flow and return)

These are the main inlet/outlet ports and are usually the largest ports on the travel motor.

Where there are four or more ports they will nearly always be located in the centre of the manifold.

C1 & C2 Ports (case drain)

Most modern final drives will have two case drain ports, one on either side of the A/B ports.

The position of the drain port can be changed by placing a plug in either C1 or C2.

It is important to always attach the case drain hose to the uppermost port and leave the bottom port plugged. Some drives have a single case drain port between the A/B ports.

In smaller drives the twin speed hose/port and case drain hose/port are the same size so it is critical that the case drain hose is correctly identified.

Attaching a pressurized hose to this port can cause both hydraulic and mechanical failure. If plumbed incorrectly you WILL cause damage to the final drive. Be absolutely sure which line is which before connecting the hoses. If in doubt, contact your local FDC Partner.

All conventional axial piston hydraulic motors must have a controlled leakage from the rotating group (motor) into the casing. This oil lubricates all moving parts within the rotating group and it MUST be able to drain back to the hydraulic tank relatively unrestricted via the swivel joint and return line filter.

The case drain oil also lubricates both motor shaft bearings. It is important that the case drain hose is connected to the uppermost case drain port (where there is an option) so the motor case is constantly full of oil.

If the case drain port is not connected or becomes blocked, the pressure inside the motor case will build, causing catastrophic damage to the motor and usually the gearbox.

D Port (Two Speed)

The two speed port tends to be the smallest on the travel motor and can be found in different positions depending on the model and manufacturer.

It can be found on the front of the manifold centred between the A/B ports or located on the side or rear of the manifold.

Brake Port

With the exception of tracked dumpers and other faster moving tracked machines it is unusual to find a brake port in an integrated gearbox and travel motor as the brake is usually controlled automatically.

Where a separate “plug-in” motor is used the brake port is usually found on the gearbox. If equipped the port location will be clearly shown in the installation instructions.

and Dyco?

and Dyco?