Travel Motor Hydraulic Port Identification

Single Speed Final Drives

1.5T Mini Excavator

Single speed orbital type travel motor showing 2 entry ports. Note there is no need for a case drain port on this motor.

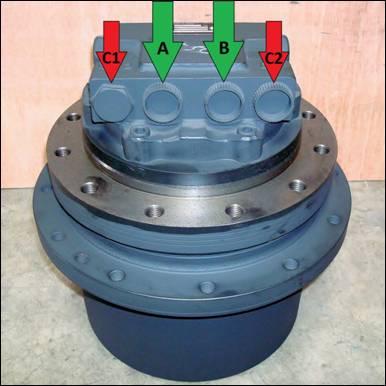

8T Mini Excavator

Integrated single speed travel motor showing 4 front entry ports. The C ports are interconnected and either can be used.

2 Speed Integrated Final Drives

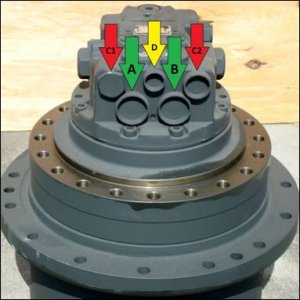

3T Mini

Integrated two speed travel motor showing 5 front entry ports. The case drain ports are interconnected and either can be used.

13T Excavator

Integrated two speed travel motor showing 5 front entry ports. The case drain ports are interconnected and either can be used.

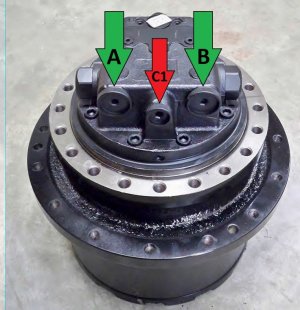

3.5T Mini

Motor showing 4 front entry ports. Either of the C ports can be used.

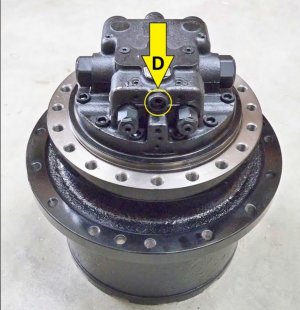

3.5T Mini

Integrated two speed travel motor with the two speed port to the side.

12T Excavator

Case drain port is between A/B ports.

12T Excavator

The two speed port is at the rear.

20T Excavator

Case drain ports are either side of A/B ports.

20T Excavator

The two speed port is at the rear.

Single Speed Final Drives

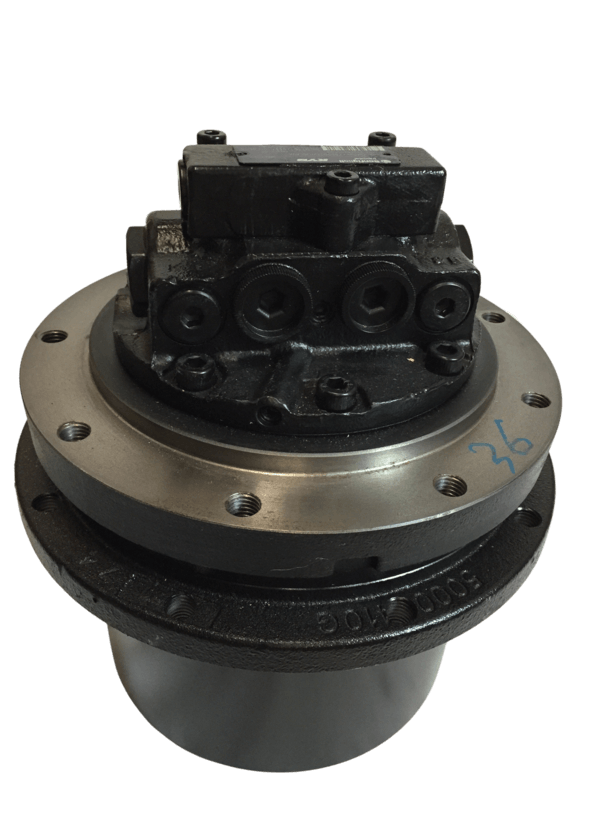

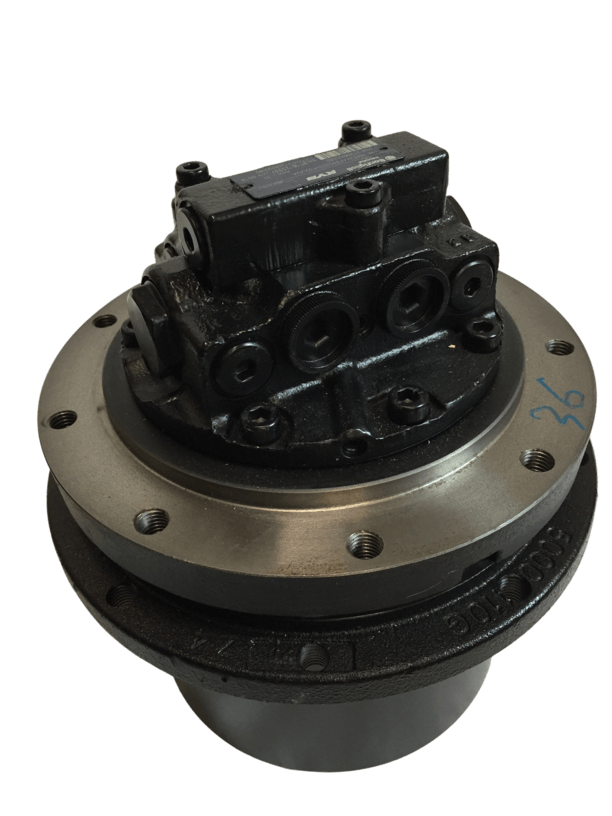

36T Excavator

'Plug in' 2 speed travel motor and gearbox.

36T Excavator

Alternative C port out of view.

and Dyco?

and Dyco?